Introduction

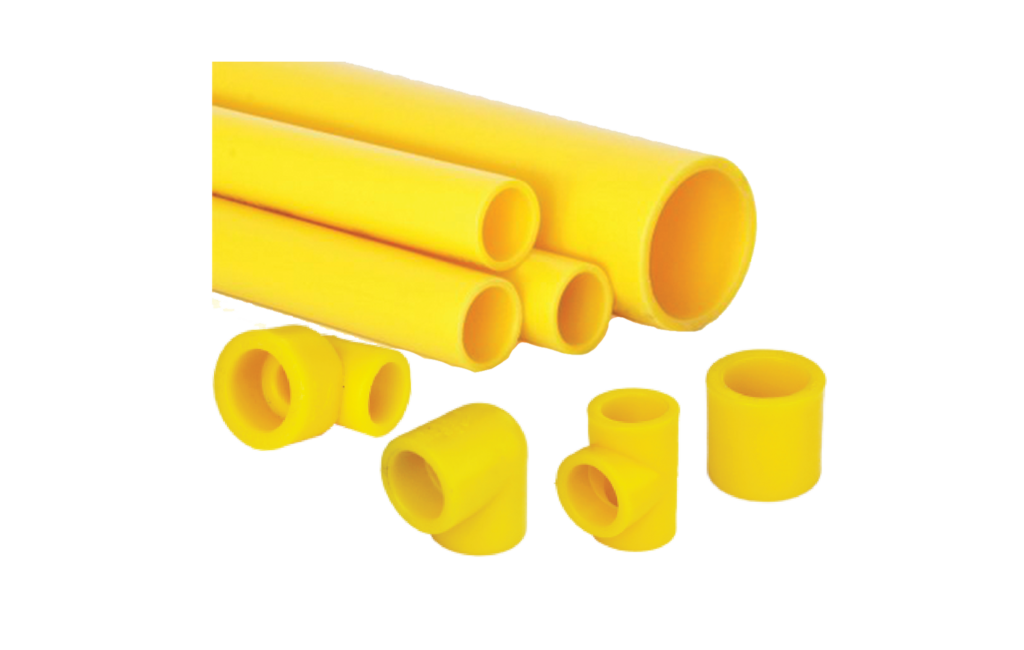

In the realm of modern construction and infrastructure, MDPE (Medium-Density Polyethylene) pipes and fittings have transcended their conventional role in plumbing systems. The remarkable versatility, durability, and flexibility of MDPE have led to its adoption in various groundbreaking applications across industries. Plasco Pipes, a pioneering name in the field, has been at the forefront of this revolution, pushing the boundaries of MDPE’s potential. In this article, we will delve into the innovative uses of MDPE pipes and fittings beyond traditional plumbing, examining how Plasco Pipes and other materials like HDPE and PPRC are transforming industries.

The Evolution of MDPE Pipes & Fittings

MDPE pipes and fittings have a rich history, starting primarily as reliable components of water supply and drainage systems. Over time, their composition and characteristics have been fine-tuned to increase their strength, corrosion resistance, and longevity. This evolution paved the way for MDPE’s expansion beyond plumbing, proving its mettle in applications that demand exceptional performance under diverse conditions.

Infrastructure and Gas Distribution

MDPE’s resistance to chemicals and environmental stress cracking makes it an excellent choice for gas distribution systems. Plasco Pipes, a renowned manufacturer, has capitalized on MDPE’s attributes to create secure and efficient gas distribution networks. These pipes offer a safe and cost-effective solution for transporting natural gas to homes, industries, and commercial establishments.

Agriculture and Irrigation

In the agricultural sector, MDPE pipes & fittings have emerged as indispensable assets for irrigation systems. Their flexibility, durability, and resistance to UV radiation and chemicals make them ideal for transporting water over long distances while withstanding varying climatic conditions. Plasco Pipes has played a pivotal role in advancing agricultural practices through their innovative MDPE solutions.

Mining and Industrial Applications

The mining industry demands robust piping solutions that can withstand harsh conditions and transport materials efficiently. MDPE pipes, with their exceptional strength and chemical resistance, have found their way into mining operations for slurry transportation, heap leaching, and more. Plasco Pipes’ contributions to this sector have redefined safety and reliability.

Telecommunication and Cable Conduits

Beyond fluid transportation, MDPE pipes are now instrumental in housing telecommunication cables and fiber optics. Plasco Pipes’ MDPE conduits provide protection for sensitive cables against moisture, environmental factors, and physical damage. This application showcases MDPE’s adaptability to modern connectivity needs.

Geothermal Systems

Geothermal energy systems require durable pipes that can handle high temperatures and corrosive fluids. MDPE pipes have proven their worth in this domain, serving as conduits for geothermal fluids between wells and power generation plants. Plasco Pipes’ expertise in manufacturing MDPE pipes for geothermal applications underscores their commitment to sustainable energy solutions.

Environmental Solutions

The eco-friendliness of MDPE pipes, coupled with their resistance to soil chemicals, has led to their use in various environmental applications. They are utilized for landfill leachate collection, drainage systems, and rainwater harvesting projects. Plasco Pipes’ innovative approach aligns with the growing emphasis on sustainable practices.

Comparative Advantage: MDPE vs. HDPE and PPRC

While MDPE has exhibited its exceptional utility, it’s crucial to acknowledge its counterparts—HDPE (High-Density Polyethylene) and PPRC (Polypropylene Random Copolymer). Each material possesses unique properties that cater to specific needs.

MDPE vs. HDPE: MDPE is a middle-ground between low-density and high-density polyethylene. It offers improved strength and resistance compared to LDPE but remains more flexible than HDPE. HDPE Pipes & Fittings, on the other hand, is renowned for its high strength-to-density ratio, making it ideal for heavy-duty applications such as pipes for municipal water systems or industrial pipelines.

MDPE vs. PPRC: PPRC pipes & fittings are celebrated for their chemical resistance and high-temperature tolerance. They are often employed in plumbing systems for hot and cold water distribution. While MDPE shares some characteristics with PPRC, such as chemical resistance, MDPE’s greater flexibility and adaptability enable its use in diverse applications beyond plumbing.

Plasco Pipes’ Commitment to Innovation

At the forefront of these innovative applications lies Plasco Pipes—a company synonymous with quality, innovation, and reliability. Plasco’s continuous research and development efforts have expanded the horizons of MDPE pipes and fittings. With a comprehensive range of products designed to meet the requirements of various industries, Plasco Pipes has redefined the role of MDPE in modern infrastructure.

Conclusion

MDPE pipes and fittings, once relegated to the realm of plumbing, have evolved into a cornerstone of modern infrastructure across industries. Plasco Pipes’ pioneering efforts, alongside advancements in materials like HDPE and PPRC, have propelled MDPE’s adoption in gas distribution, agriculture, mining, telecommunications, geothermal energy, and environmental solutions. As we witness the continued evolution of MDPE’s applications, one thing is clear: its remarkable versatility is reshaping the way we build, connect, and sustain our world.