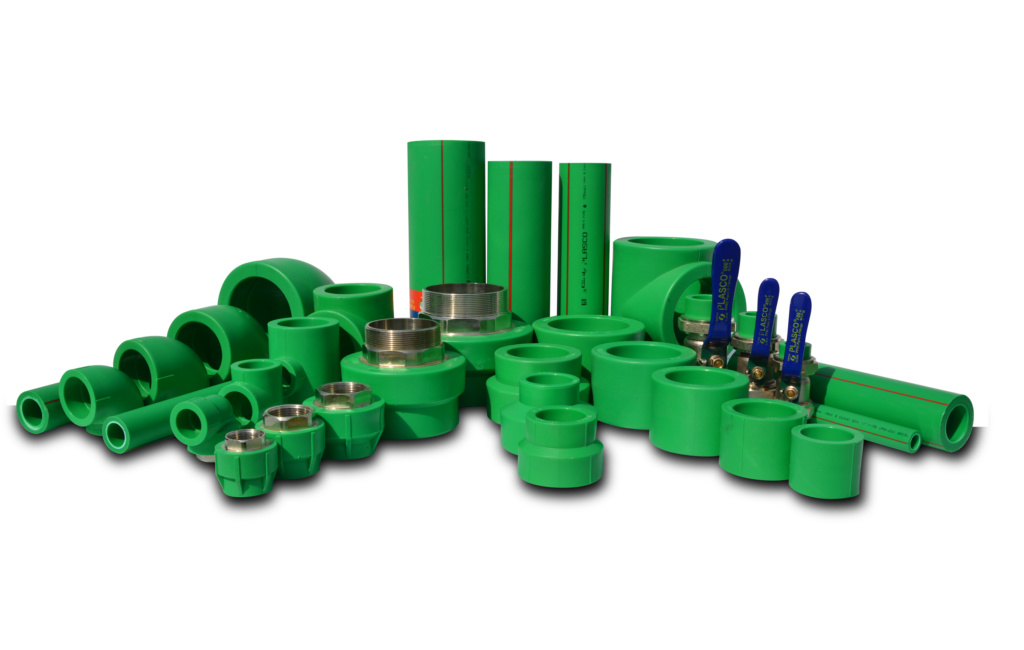

In the dynamic world of industrial and chemical processes, selecting the right materials for pipelines and fittings is of paramount importance. These pipelines are the lifelines that facilitate the flow of various substances, from corrosive chemicals to high-temperature fluids. When it comes to meeting the stringent demands of chemical and industrial applications, PPRC (Polypropylene Random Copolymer) pipes and fittings have emerged as an exceptional choice. In this blog, we will delve into the many advantages of PPRC pipes in chemical and industrial settings, with a focus on the expertise of Plasco Pipes, a leader in the field of pipes manufacturing.

Understanding PPRC Pipes and Fittings

Before we explore the specific advantages of PPRC pipes in chemical and industrial applications, let’s take a moment to understand what sets these pipes apart.

PPRC, which stands for Polypropylene Random Copolymer, is a type of plastic known for its exceptional chemical resistance, durability, and versatility. It is a thermoplastic material that is rapidly gaining popularity across various industries. PPRC pipes and fittings are widely used in plumbing, heating, cooling, and industrial piping systems due to their numerous advantages.

Key Features of PPRC Pipes and Fittings:

Chemical Resistance: PPRC materials exhibit excellent resistance to a wide range of chemicals, making them suitable for conveying corrosive substances.

High Temperature Tolerance: PPRC can withstand high-temperature fluids and is often used in hot water systems and industrial processes.

Durability: PPRC pipes and fittings have a long service life, with minimal risk of corrosion or degradation over time.

Leak-Proof: The joints in PPRC systems are typically fused or welded, reducing the risk of leakage and ensuring a reliable flow of fluids.

Lightweight: PPRC pipes are lightweight and easy to handle, simplifying installation and reducing labor costs.

Low Maintenance: These pipes are virtually maintenance-free, requiring minimal upkeep over their lifespan.

Now, let’s delve into the specific advantages of PPRC pipes and fittings in chemical and industrial applications.

Advantages of PPRC Pipes in Chemical and Industrial Applications

1. Chemical Resistance

One of the standout features of PPRC pipes is their exceptional resistance to a wide array of chemicals. Whether it’s conveying corrosive acids, bases, or solvents, PPRC pipes can handle the challenge. This is particularly critical in chemical processing plants where the integrity of the pipeline is paramount.

2. High Temperature Tolerance

In industrial settings, where processes often involve high-temperature fluids, PPRC pipes shine. They can withstand elevated temperatures without warping or deteriorating, ensuring a reliable flow of hot fluids. This makes them ideal for applications such as steam lines, hot water systems, and industrial heating.

3. Durability and Longevity

PPRC pipes are built to last. Their resistance to corrosion and chemicals means they have a longer service life compared to traditional metal pipes. This results in cost savings over time as fewer replacements and repairs are needed. In chemical and industrial applications, where downtime can be costly, this durability is a significant advantage.

4. Leak-Proof Joints

The joints in PPRC systems are typically fused or welded, creating a seamless and leak-proof connection. This is crucial in chemical and industrial applications where even a small leak can result in product loss, safety hazards, and environmental concerns. The reliability of PPRC joints is a significant asset.

5. Lightweight and Easy Installation

PPRC pipes are remarkably lightweight compared to metal alternatives. This makes them easier to transport and handle during installation, reducing labor costs and the need for heavy machinery. Quick and efficient installation is a key advantage, especially in industrial settings with tight schedules.

6. Low Maintenance

Once installed, PPRC pipes require minimal maintenance. Unlike metal pipes that can corrode or scale over time, PPRC pipes remain smooth on the inside, ensuring efficient fluid flow. This low-maintenance characteristic is particularly beneficial in industrial environments where downtime for maintenance can be disruptive and costly.

Plasco Pipes: Pioneering Excellence in Pipes Manufacturing

Plasco Pipes, a distinguished name in the pipes manufacturing industry, has played a pivotal role in advancing the use of PPRC pipes and fittings in chemical and industrial applications. With their commitment to quality and innovation, Plasco Pipes has consistently delivered reliable and sustainable piping solutions to various industries.

Why Choose Plasco Pipes for PPRC Solutions?

Expertise: Plasco Pipes possesses a wealth of knowledge and expertise in PPRC materials, ensuring that their products meet the specific requirements of chemical and industrial applications.

Innovation: Plasco Pipes invests in research and development to continually improve their PPRC pipes and fittings, incorporating the latest advancements in materials and manufacturing techniques.

Quality Assurance: Plasco Pipes adheres to stringent quality control measures to guarantee the durability and performance of their products, meeting industry standards and regulations.

Custom Solutions: Recognizing that every industrial or chemical process is unique, Plasco Pipes offers customized PPRC solutions tailored to the specific needs of each application.

Environmental Responsibility: Plasco Pipes is committed to sustainable practices, ensuring that their PPRC products are eco-friendly and recyclable, contributing to a greener future.

Applications of PPRC Pipes in Chemical and Industrial Settings

The advantages of PPRC pipes extend to various applications within chemical and industrial environments:

Chemical Processing Plants: PPRC pipes are a reliable choice for conveying a wide range of chemicals, acids, and bases.

Pharmaceutical Industry: The exceptional cleanliness and chemical resistance of PPRC make it suitable for pharmaceutical manufacturing processes.

Food and Beverage Industry: PPRC pipes are used for transporting hot fluids, including those required for food processing and pasteurization.

Textile Industry: In dyeing and finishing processes that involve high-temperature water, PPRC pipes ensure efficient heat transfer.

Power Plants: PPRC pipes are employed for cooling water systems and handling high-temperature fluids in power generation facilities.

Metal Processing: In metal plating and finishing operations, where corrosive substances are present, PPRC pipes excel.

Conclusion

PPRC pipes and fittings have become a linchpin in the world of chemical and industrial applications. Their exceptional chemical resistance, high-temperature tolerance, durability, and ease of installation make them a preferred choice for industries that demand reliability and efficiency.

Plasco Pipes, a leader in pipes manufacturing, has played a pivotal role in advancing the use of PPRC materials in various industries. With a commitment to quality, innovation, and sustainability, Plasco Pipes exemplifies the potential of PPRC solutions in addressing the complex demands of chemical and industrial applications.

By choosing PPRC pipes and fittings from companies like Plasco Pipes, industries can not only meet their immediate operational needs but also contribute to a more sustainable and environmentally responsible future. It’s a testament to the power of modern materials and innovative manufacturing techniques in transforming industries and shaping a better tomorrow.