In today’s world, environmental sustainability is a top priority. Industries and individuals alike are constantly seeking ways to reduce their carbon footprint and minimize their impact on the environment. One area where significant progress has been made is in the development and use of environmentally friendly materials in construction and infrastructure projects. UPVC (Unplasticized Polyvinyl Chloride) pressure pipes and fittings are one such innovation that offers numerous environmental benefits, and Plasco Pipes is a leading company at the forefront of this movement. In this blog, we will explore the environmental advantages of UPVC pressure pipes and fittings and how Plasco Pipes, a pioneer in the industry, is contributing to a greener future.

The Environmental Challenge

Before delving into the environmental benefits of UPVC pressure pipes and fittings, it’s essential to understand the environmental challenges that the construction and infrastructure industries face. Traditional materials and methods often have negative impacts on the environment. For instance, the production of steel and concrete involves significant energy consumption and greenhouse gas emissions. Additionally, materials like asbestos and lead, once commonly used in pipes and fittings, are known to be hazardous to both human health and the environment.

This environmental challenge prompted a search for more sustainable alternatives that could meet the demanding requirements of construction and infrastructure projects while also minimizing harm to the environment. UPVC pressure pipes and fittings emerged as a promising solution.

Understanding UPVC

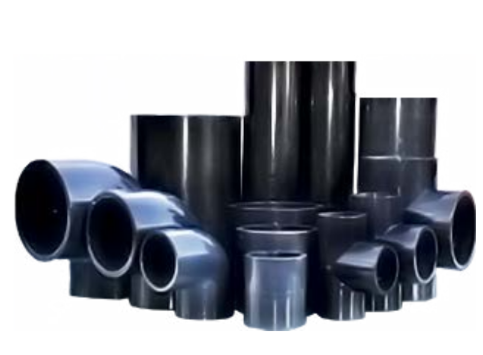

UPVC, or Unplasticized Polyvinyl Chloride, is a type of plastic known for its durability, versatility, and sustainability. Unlike traditional PVC, UPVC does not contain plasticizers, making it rigid and resistant to bending. This unique property is particularly advantageous in the construction of pipes and fittings, where structural integrity is critical.

Key Features of UPVC Pressure Pipes and Fittings:

Durability: UPVC is highly durable and can withstand harsh environmental conditions, including exposure to chemicals and UV radiation. This durability ensures that UPVC pipes and fittings have a long lifespan, reducing the need for frequent replacements.

Corrosion Resistance: UPVC Pressure Pipes & Fittings is naturally resistant to corrosion, making it an ideal material for transporting various fluids, including water and chemicals. This corrosion resistance minimizes the risk of leaks and contamination.

Low Maintenance: UPVC pipes and fittings require minimal maintenance over their lifespan, further reducing the environmental impact associated with maintenance activities.

Recyclability: UPVC is recyclable, allowing for the reuse of materials at the end of their life cycle. This reduces waste and conserves resources.

Energy Efficiency: The production of UPVC pipes and fittings consumes less energy compared to alternatives like steel or concrete.

Plasco Pipes: Leading the Way in Sustainable Solutions

Plasco Pipes is a renowned company known for its commitment to providing sustainable and environmentally friendly solutions for the construction and infrastructure sectors. They have been at the forefront of the UPVC pressure pipes and fittings industry, setting high standards for quality and environmental responsibility.

Plasco’s Contribution to Environmental Sustainability:

Quality Assurance: Plasco Pipes places a strong emphasis on quality assurance to ensure that their UPVC pressure pipes and fittings meet or exceed industry standards. This commitment to quality reduces the likelihood of defects or failures, which can lead to environmental damage.

Research and Development: Plasco invests in ongoing research and development to improve the performance and environmental sustainability of UPVC products. They actively seek innovative ways to enhance their products’ efficiency and reduce their environmental footprint.

Recycling Initiatives: Plasco Pipes is dedicated to recycling UPVC materials to minimize waste. By recycling, they reduce the need for new raw materials and decrease the environmental impact associated with manufacturing.

Energy Efficiency: Plasco continually seeks to optimize their manufacturing processes to reduce energy consumption. This not only lowers production costs but also contributes to a greener future.

Customer Education: Plasco Pipes is committed to educating customers about the environmental benefits of UPVC pressure pipes and fittings. Through knowledge sharing and awareness campaigns, they empower customers to make informed choices that support sustainability.

Environmental Benefits of UPVC Pressure Pipes and Fittings

Now, let’s delve deeper into the specific environmental benefits of UPVC pressure pipes and fittings.

Reduced Carbon Footprint

UPVC is known for its low carbon footprint compared to traditional materials like steel and concrete. The production of UPVC pipes and fittings consumes less energy and generates fewer greenhouse gas emissions. This reduced carbon footprint is a crucial aspect of sustainable construction and infrastructure projects, aligning with global efforts to combat climate change.

Longevity and Durability

UPVC pressure pipes and fittings have a significantly longer lifespan compared to many alternative materials. Their resistance to corrosion and deterioration ensures that they can operate efficiently for decades without needing frequent replacements. This longevity not only reduces maintenance costs but also lessens the environmental impact associated with manufacturing and disposal.

Chemical Resistance

UPVC is inherently resistant to many chemicals, making it a safe choice for transporting various fluids, including corrosive substances. The reduced risk of leaks and contamination not only protects the environment but also safeguards public health.

Minimal Maintenance

The low-maintenance requirements of UPVC pressure pipes and fittings result in fewer disruptions and maintenance activities over their lifetime. This translates to less resource consumption, reduced waste generation, and lower overall environmental impact.

Recyclability

One of the standout environmental benefits of UPVC is its recyclability. At the end of their useful life, UPVC pipes and fittings can be recycled and used to manufacture new products. This closed-loop recycling system conserves resources and reduces the demand for virgin materials.

Reduced Water Loss

UPVC pipes have low friction properties, which contribute to efficient water flow. This efficiency helps minimize water loss due to friction and leaks. Conserving water resources is a critical aspect of environmental sustainability, particularly in regions facing water scarcity.

Energy Efficiency

The energy efficiency of UPVC production processes further enhances their environmental appeal. Lower energy consumption during manufacturing translates to reduced greenhouse gas emissions and a smaller overall environmental footprint.

Comparing UPVC with Other Materials

To better appreciate the environmental benefits of UPVC pressure pipes and fittings, it’s essential to compare them with alternative materials commonly used in construction and infrastructure projects, such as HDPE (High-Density Polyethylene) pipes and fittings and SWV (Steel Wire Reinforced Vinyl) pipes and fittings.

UPVC vs. HDPE Pipes & Fittings

HDPE is another popular choice in the construction industry due to its flexibility, resistance to corrosion, and lightweight properties. However, when it comes to environmental sustainability, UPVC offers several advantages:

Durability: While both UPVC and HDPE pipes are durable, UPVC has been proven to have a longer lifespan, reducing the frequency of replacements and associated environmental impacts.

Recyclability: UPVC is more readily recyclable than HDPE. This means that UPVC pipes have a higher potential for closed-loop recycling and resource conservation.

Chemical Resistance: UPVC’s superior chemical resistance makes it a safer option for transporting a wide range of fluids, especially in industrial settings.

UPVC vs. SWV Pipes & Fittings

SWV pipes and fittings are often used for drainage and sewage systems. When comparing UPVC with SWV in terms of environmental benefits:

Chemical Resistance: UPVC offers better chemical resistance, which is crucial for sewage and drainage systems where exposure to corrosive substances is common.

Longevity: UPVC’s durability ensures that sewage and drainage systems can function efficiently for extended periods, reducing the need for frequent replacements.

Recyclability: UPVC is more readily recyclable than SWV, contributing to a circular economy and reduced resource consumption.

Conclusion

In a world where environmental sustainability is a pressing concern, UPVC pressure pipes and fittings stand out as a viable and eco-friendly solution for construction and infrastructure projects. The environmental benefits of UPVC, including reduced carbon footprint, longevity, chemical resistance, minimal maintenance, recyclability, and energy efficiency, make them an excellent choice for those looking to minimize their environmental impact.

Plasco Pipes, as a leading company in the field, plays a pivotal role in promoting these environmental benefits and driving innovation in the industry. Their commitment to quality, recycling initiatives, energy efficiency, and customer education demonstrates their dedication to a greener and more sustainable future.

As we continue to address the environmental challenges of our time, it’s crucial to recognize the significance of materials like UPVC pressure pipes and fittings and companies like Plasco Pipes that prioritize environmental sustainability. By choosing UPVC over traditional materials and supporting environmentally conscious companies, we can collectively contribute to a more sustainable and eco-friendly world.